Wawa

Michipicoten City

In the beginning God created the heaven and the earth. And the earth was without form, and void; and darkness was upon the face of the deep. And the Spirit of God moved upon the face of the waters. And God said, Let there be light: and there was light.

The light was so bright and so hot in the instant of creation that nothing else could exist, just the light. But within a second the light cooled to the point that simple particles - neutrinos, quarks and electrons - could form, although it was still too hot for them to stick together. That would be about three minutes later, in the era of nucleosynthesis, when atomic nuclei were formed. Nucleosynthesis would last for 20 minutes into the creation and after that there would be no further nuclei. But the light and heat of creation was still too strong for any stability, and the first hydrogen atoms, the simplest form of atom, would form and then be blown apart, over and over, for 380,000 years. This is the point at which God's creation had expanded and cooled sufficiently for atoms of one or two, or in rare cases, three or four proton-electron pairs plus the odd neutron to form, release their excess energy in the form of photons of light, and remain stable. Hydrogen, a little Helium and a minuscule amount of Lithium and Beryllium were formed in this way. And that was about it for over 250 million years. Just a giant expanding sea of mostly hydrogen.

And [then] God said, Let there be a firmament in the midst of the waters, and let it divide the waters from the waters. And God made the firmament, and divided the waters which were under the firmament from the waters which were above the firmament: and it was so.

The vast oceans of hydrogen gas started to coalesce, to divide, into small proto-galaxies as little as 30 light years across - .0015% as large as the Milky Way. These proto-galaxies were all that the creation contained for another 150 million years. There were no stars, no planets; nothing solid. But then a curious thing happened.

And [finally] God said, Let there be lights in the firmament of the heaven to divide the day from the night; and let them be for signs, and for seasons, and for days, and years... : and it was so.

The first generation of stars, the Population III stars, condensed out of the proto-galaxy stew and became so dense and compacted that the hydrogen got squished, or fused, into larger atoms, mostly helium, releasing excess energy again in the form of light. The new suns flared into brilliant blue-white life, and had a violent and brief existence, flooding the creation with visible light. And then, over a brief period, they all died.

But when a star dies, the "stuff" it has created remains, coalesces again, and if enough of it clumps together, once more turns into a star, and continues to combine into heavier and heavier atoms. The Population II stars are the oldest stars we can find in the universe today; they are considered metal poor. In chemistry, a metal is a solid that can conduct electricity; in astronomy, where the concepts of both solid and electricity are subject to interpretation, a metal is an element that is neither hydrogen nor helium. So the process of converting the original Hydrogen that God had called into existence, some 13.8 billion years ago from where we sit, into heavier elements carried on with the Population II stars and again with the Population I stars. Our sun is a Population I star.

The sun is roughly 75% hydrogen and 25% helium, and converts about 600 million tons of its hydrogen into helium every second. It is considered to be on the smaller side of average with a radius of less than 700,000 km and, more importantly, a current mass of only around a third of a million times the mass of the Earth. As a relatively small star it can't generate the pressures involved in metal fusion, and so it will only ever convert hydrogen into helium. But a star that is at least eight times as massive as our star, let's say one like VV Cephei, which is hundreds of times larger than our sun, will have several spheres within it, all fusing different elements. The outermost shell, where the pressures and heat are the least, will be hydrogen with one proton. The next shell will be hydrogen that has been fused into helium, two protons. Since everything else is made from helium, it is easier to create elements with even numbers of protons, as you go deeper into the star: carbon (6), then oxygen (8), neon (10), magnesium (12), silicon (14) and sulfur (16) until, finally, at the core, iron with 26 protons. Of course, stellar nuclear fusion being more of an art and less of an exact science, all of the intermediate elements up to iron are also being made along the way, odd protons or not. But iron is the end of the exothermic line - the processes that give off energy. To get a heavier element, let's say gold, you need to add energy by way of a collision or an explosion or some such. That is why there is an abundance of iron in the universe as compared to gold. Fortunately, for the gold enthusiasts, once a star starts producing an iron core its fuse is lit, and it is going to explode. But that still leaves a universe that, as far as metals are concerned, is mostly iron.

The Earth, for instance, is mostly iron. Followed by oxygen, silicon, magnesium and sulfur. Which sort of makes sense if you consider the shells in a supergiant star prior to its exploding and recycling itself into planets, such as the Earth. Iron is quite dense, and tends to settle at the planet's core, or maybe it condenses first, being heavier. In any event, the lighter elements tend to be on the top layers. So the very top layer of the earth is mostly gaseous oxygen and nitrogen, the gaseous hydrogen being so light that it is more a part of the Sun's atmosphere than our own. In between the core and the atmosphere is the crust, the top little bit of solid planet that we live on. It is mostly silicon and aluminum, lighter elements. But it is still 5 percent iron. The trick is to get it into a useable form.

Elements on the Earth's surface are almost never pure. Nitrogen and Oxygen, for instance, are mostly found stuck together with something else, even if it is only another atom of themselves. Silicon does not occur naturally, but you will often find it stuck to some oxygen and calling itself Silica which you might call rock or sand. Aluminum is more likely to be Bauxite, and Iron is generally to be found in the form of iron oxides (rust) mixed in, at the molecular level, with silicas and/or carbon, and then these will be mixed generally together with other molecules of whatever's convenient - more silica or sulfur perhaps. These mixtures, when you get enough of them together in one place, are called iron ore, which by itself is every bit as useful as any other rock. But if you can reduce the iron out from its ore, remove the molecular impurities such as oxygen, then you have something.

People first started using iron for weapons and tools as early as the 14th century B.C.E. But it was very hard to come by, and worth much more than gold. King Tutankhamun had a dagger made of iron - stainless steel actually - but the metal had come from a meteorite. At the time, copper, and its alloy, bronze, were much more common because you can smelt copper from its ore in a pottery kiln, or, if you are lucky, simply find lumps of it laying about. Iron, on the other hand, doesn't melt until it reaches a temperature of 1,538 degrees Celsius, far hotter than a kiln, and it also has to be reduced - something has to be added that wants the oxygen in the ore more than the ore does. But with the addition of a few vents, maybe some form of bellows, you can turn your pottery kiln into a bloomery, a sort of really hot oven. If you fire your bloomery with pure charcoal, keep the air flowing well, and then stuff it full of iron ore mixed about half and half with more charcoal as a reducing agent, your bloomery will easily reach temperatures of 680 degrees Celsius, at which point the blooming process begins. If you can get your bloomery up to 900 degrees celsius the process is very much faster. The blooming process is the reduction of iron ore into a kind of lumpy slag that becomes more and more concentrated iron the lower you go in the bloomery. So as the charcoal burns and the slag settles, you add more ore and charcoal to the top and keep going. Eventually, you get a big lump of iron/slag red hot goo at the bottom, a bloom. A bloom, when hammered, or wrought, breaks off chunks of slag and sparks of impurities and turns into wrought iron. And this is the way that iron ore was refined starting around 1200 B.C.E. until the blast furnace arrived - 1491 in Wales; much earlier in China.

Over the years, the process of creating iron, and then steel (iron with the addition of carbon to make it stronger) has evolved into less of an art and more of a science. But it still starts with iron ore. There are five main types of iron ore, in descending order of iron content and therefore quality: magnetite, the stuff you could harvest on your own when I was a kid by sliding a magnet wrapped in a piece of paper through sand; hematite; goethite; limonite; and, lastly, siderite. Magnetite is practically iron already: you can magnetize it, hence the magnet and paper thing. But while magnetite is rich in iron, magnetite deposits are generally not rich in magnetite, often containing more hematite. Hematite, while being slightly less pure than magnetite, is much more prevalent and easily mined. It is also still a direct shipping ore, which means you dig it up, maybe crush it a bit, but then ship it off to the furnace wherever that may be. Goethite is formed by the weathering of other iron rich minerals and tends to be found in bogs or the bottoms of lakes. Also, oddly, limpet's teeth are mostly goethite. A small patch of goethite has even been found on Mars, further supporting the idea that liquid water was once prevalent on the rusty planet. Further down the list, limonite is a useful iron ore, but its purity is too low to be considered a direct-shipping ore, and it requires processing at the mine. And lastly, siderite is generally contaminated with impurities such as sulfur making it a poor ore. In the early 1900s it was more useful as an indicator of where the gold was. So at the turn of the 20th century, if you're after iron, you want hematite. Which brings us to the Canadian Shield.

The Canadian Shield is a vast region of rock almost as large as Canada and almost as old as the planet itself. As such, it has a lot of minerals that you might associate more with the inner workings of the planet than with the surface. These minerals are distributed unevenly around the shield, because the shield really isn't one contiguous geological thing. It is seven. Back when the earth was fairly new, and things were still sorting themselves out, seven distinct blocks of crust, called "provinces", rammed together and formed what would become the Canadian Shield. They moved around somewhat over the years, but nowadays they seem pretty happy where they are. To the north and west we have the Bear Province, which has copper and uranium deposits. South of that we have the Slave Province, currently being explored for diamonds. South and east of that we find the Churchill Province, rich in uranium, lead and zinc, as is the Grenville Province, to the far east of Québec and into Southern Ontario. The top little bit of Labrador is the Nain Province, rich in rock and that's about it. Bits of Ontario around Sudbury and Thunder Bay are the Southern Province, which is good for copper and nickel and amethyst if you're a rock hound. But by far the richest region is the Superior Province, most of Northern Ontario outside of the Hudson's Bay watershed. In this province you can find copper, gold, silver, and large amounts of iron ore.

Very roughly in the middle of the Superior Province is Wawungonk, the Place of Clear Water, Wawa Lake. This is in the traditional home of the Michipicoten Anishnabe people who lived in the region time out of mind. When the French arrived the region became important as a branch office of sorts for Fort Kaministiquia near present day Thunder Bay, gateway to the furs of central New France, which we'll get into more tomorrow. The Michipicoten area was also where you could hang a left (or a right, depending upon which way you were facing) and end up on James Bay by following the Missinaibi River. So the French built Fort Michipicoten nearby at the mouth of the Michipicoten River on Lake Superior. But it wasn't just furs that the French found there. They also found "copper of such excellence that pieces as large as one's fist are found, all refined". This started a bit of a mineral rush which by 1897 had turned into a gold rush. While the gold was certainly valuable, with thousands of dedicated prospectors on site it was inevitable that the region's true wealth would be discovered sooner or later.

Just a little ways to the north of Wawa Village, the new gold boomtown on the shores of Wawa Lake, Benjamin Boyer and his partners discovered a large chunk of gold-bearing mineral on his mountain property on Boyer Lake. Not being overly bright, he showed it to his boss at the Ontario and Sault Ste. Marie Water, Light and Power Company. Francis Hector Clergue was a man of many interests, and in addition to being a founding partner in the power company, was also the owner of St. Mary's Paper on the shores of the St. Mary's River in Sault Ste. Marie. And a gold mine just beside Boyer's claim, Grace Gold Mine, named in honour of his sister Grace. Clergue quickly determined that the mineral in question was not gold, but was in fact high quality red hematite. He took a two month option on Boyer's claim and the adjoining Sayer claim for the modest sum of fifty bucks. There was no gold there, after all. Test digging was producing limonite, which was valuable but not overly so. Soon enough, though, they started finding the red hematite. So Clergue exercised his option and five hundred bucks later owned the entire mountain and then built Ontario's first large scale iron mine. And as fate would have it, there was a parcel of land on the St. Mary's River in Sault Ste. Marie right beside his paper plant that would be the perfect place to build a steel mill. But it would take a few years to get Algoma Steel up and running.

In the meantime, Helen Mine (Helen was another of Clergue's sisters) on newly renamed Helen Mountain was producing a bumper crop of hematite. It was sent to the States for processing initially. But Clergue was busily building the 13 mile Algoma Central Railway between Helen Mine and the harbour at the old fur post at the mouth of the Michipicoten River. He also purchased four steamships from England, and created the Algoma Central Steamship Lines. Together, his railway and steamships could ship his ore down the lake to the Canadian Blast Furnace Company in Midland, Ontario, while he was finishing up his new steel plant at the Soo. This was the beginning of purely Canadian steel.

All of this was costing a fortune. But Clergue was exceptionally good with his money. By 1900 he had over 430 employees at the mine but still managed to keep his yearly payroll around the $100,000 mark - about one twelfth what you would pay for 430 miners and support staff in Sudbury at the time. But he could still attract people because he built a modern town for them to live in. It had a school, a slaughterhouse, a lodge, water, electricity, sewers and even a doctor. So when the gold boom turned into a bust in 1907 and Wawa Village became a ghost town, Helen Mine was the centre of civilization in the entire Michipicoten region.

No mine produces forever, though, and the Algoma Steel Corporation was well aware of this fact. When a large deposit of iron ore was discovered 12 miles north on the Magpie River in 1909 they immediately bought the claim, expanded the Algoma Central Railway with a new spur, and by 1913 everything was ready to start processing iron ore - which turned out to be siderite, and only about 35% pure. You need it at least 50% before you ship it to the steel mill. So they had to shut it all down for a year to redesign the roasting plant.

Roasting of high-sulfur iron ore is easy enough. Around the turn of the 20th century all you did was create a large layer of sulfated iron ore - siderite - and build a great huge fire on top of it. After it got good and hot the sulfur itself would catch and when the fire burned down you had matte, a shippable iron slag, with about 50% iron content. And you also had lots of sulfur by-products. The sulfur dioxide would simply waft away on the breeze, and the sulfuric acid would harmlessly dissipate into whatever wetland was nearby. That's why you did your roasting, or sintering, out in the wilds where it couldn't hurt anything. So there was an easy solution to making the mine profitable.

Things were going so great at the new Magpie mine that it produced well over 90,000 tons of roasted ore in its first six months of operation. Of course a town was needed for the miners and staff, so the town of Magpie Mine was built, much like the one at Helen Mine. It had bunkhouses for the single men, homes for families, a hospital, and a company store, all fully serviced with electricity, sewer and water. The Michipicoten area was booming. But a boom inevitably leads to a bust. It turned out that the biggest consumer of Canadian steel at the time was the railroad, which we'll talk more about another day. For now, though, we'll just say that the third and final phase of transcontinental railroads, the National Transcontinental Railway between Winnipeg and Moncton, passed right through northern Ontario, and the Algoma Central and Hudson's Bay Railway was expanded to link the steel plant at the Soo through 300 miles of mostly nothing to Hearst, a major stop on the new National line. But the bulk of the transcontinental was a wrap by 1913. The Magpie mine ceased operations again after only another six months as iron prices plummeted. What was needed was a war.

The War to End All Wars, the Great War, the First World War, traces its beginnings to 28 June 1914 when the terrorist group The Black Hand attempted to assassinate Archduke Franz Ferdinand, heir presumptive to the Austro-Hungarian Empire. To ensure success they lobbed a hand grenade at him. And missed. Franz was unscathed, and later visited the hospital where the people who intercepted his grenade were staying. On the way back his car took a wrong turn and happened right by the terrorists who were walking home. Well the rest is, as they say, history, and it couldn't have come at a better time for the Magpie mine.

In 1916 the new mine produced over 210,000 tons of ore, almost twice as much as the Helen Mine had ever produced. Now that the Helen was getting down to less concentrated ores, it was shipping its ore north to Magpie for sintering. But eventually the war was over; both the Helen and the Magpie were dying out. By 1918 the town of Helen Mine was a ghost town, finally burning to the ground in 1921, about the same time that Magpie Mine itself became a ghost town. The population of Michipicoten went from a high of 1,001 in the 1911 census to 10% of that in the 1921 census. What was needed was another war.

Adolf Hitler invaded Poland in September of 1939, setting off a war that would see over 68 million direct deaths, uncountable collateral deaths and a much needed revitalization of the Canadian steel industry. Suddenly steel was in great demand - steel to shoot at people, drop on people, and sink from underneath people. And so the previously unprofitable and closed down Helen and Magpie mines were reopened, and a new town was built - Sinterville - to service the new sintering plant for the two mines. Another town was built nearby for those not directly involved in sintering (sintering plants were pretty smelly) which was called Siderite. But both of the new towns were built very near the old ghost town of Wawa, which saw a resurgence as a result. Wawa had the distinction of being a passenger station on the Algoma Central (and Hudson's Bay) Railway. Over time, the mines came and went, along with any buildings they had. But the town of Wawa continued, mostly because that's the place you could get to. But only by passenger rail. What was needed was a highway.

By 1960 the Sault - Wawa portion of "The Big Gap" in Highway 17, between the Agawa River north of the Sault, and Marathon, on the north shore of Lake Superior, arguably the prettiest highway on Earth, was completed and opened to traffic. It was now possible to drive to Wawa, and tourism was becoming a possible way of smoothing out the economic bumps on the mining rollercoaster. The problem was that the Trans-Canada Highway bypassed the little town of Wawa by a good mile. People driving from Manitoba to Quebec or vice versa would need a reason to come into town. What was needed was a giant goose.

Wawa is an Ojibwe word meaning Wild Goose. So as the new highway 17 was being completed and local entrepreneur Al Turcott (Turcott's Dry Goods and Clothing) decided the town needed a tourist attraction, he built a twenty-four foot tall mesh and plaster goose to entice visitors to come to town and view the messy wreckage. It turns out that mesh and plaster tops the list of things not to build a giant goose out of in northern Ontario. But the idea seemed sound, so three years later, the brand new steel goose, made out of ore from the Helen Mine, was unveiled to a breathless public. Against all reason it was a success, attracting over 100,000 visitors each year, one of whom was Stompin' Tom Connors who wrote a song about it.

Of course, even a steel goose doesn't last forever, so in 2017 it was replaced with the current one, a $300,000 three tonne monument to Wawa's local minerals. And its convoluted past.

Looks like our spell of good weather is holding. That's unusual this time of year.

Looks like our spell of good weather is holding. That's unusual this time of year.

|

We'll be over Georgian Bay for a good half an hour to start.

We'll be over Georgian Bay for a good half an hour to start.

|

And then bush of course.

And then bush of course.

|

And the odd little town like Massey here.

And the odd little town like Massey here.

|

And Elliot Lake. Once the Uranium Capital of the World, it is now known more for its expertise in reclaiming old mines to a more natural state, so that they can become retirement destinations.

And Elliot Lake. Once the Uranium Capital of the World, it is now known more for its expertise in reclaiming old mines to a more natural state, so that they can become retirement destinations.

|

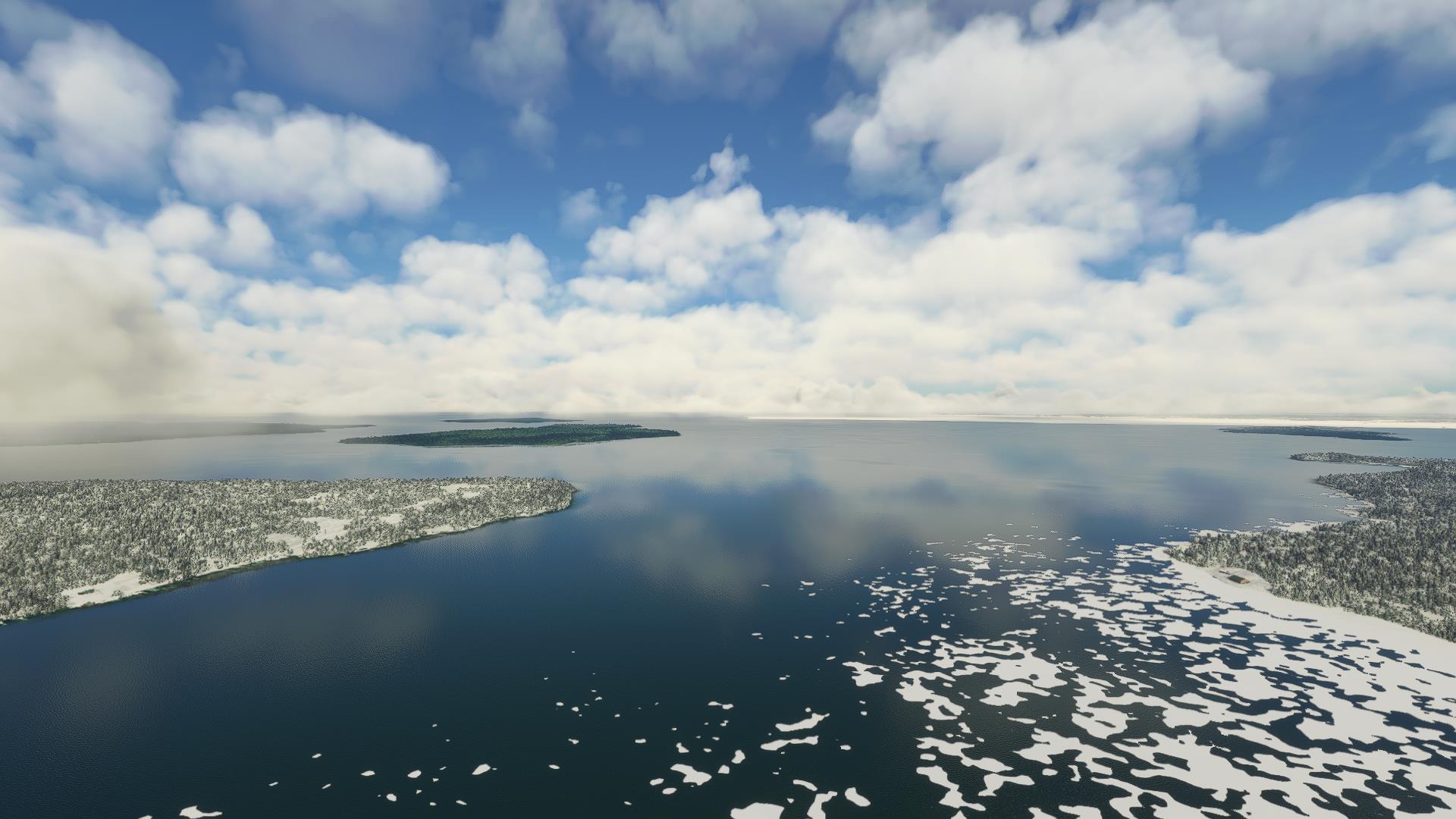

Montreal Lake and River. A good way to get into the interior by canoe.

Montreal Lake and River. A good way to get into the interior by canoe.

|

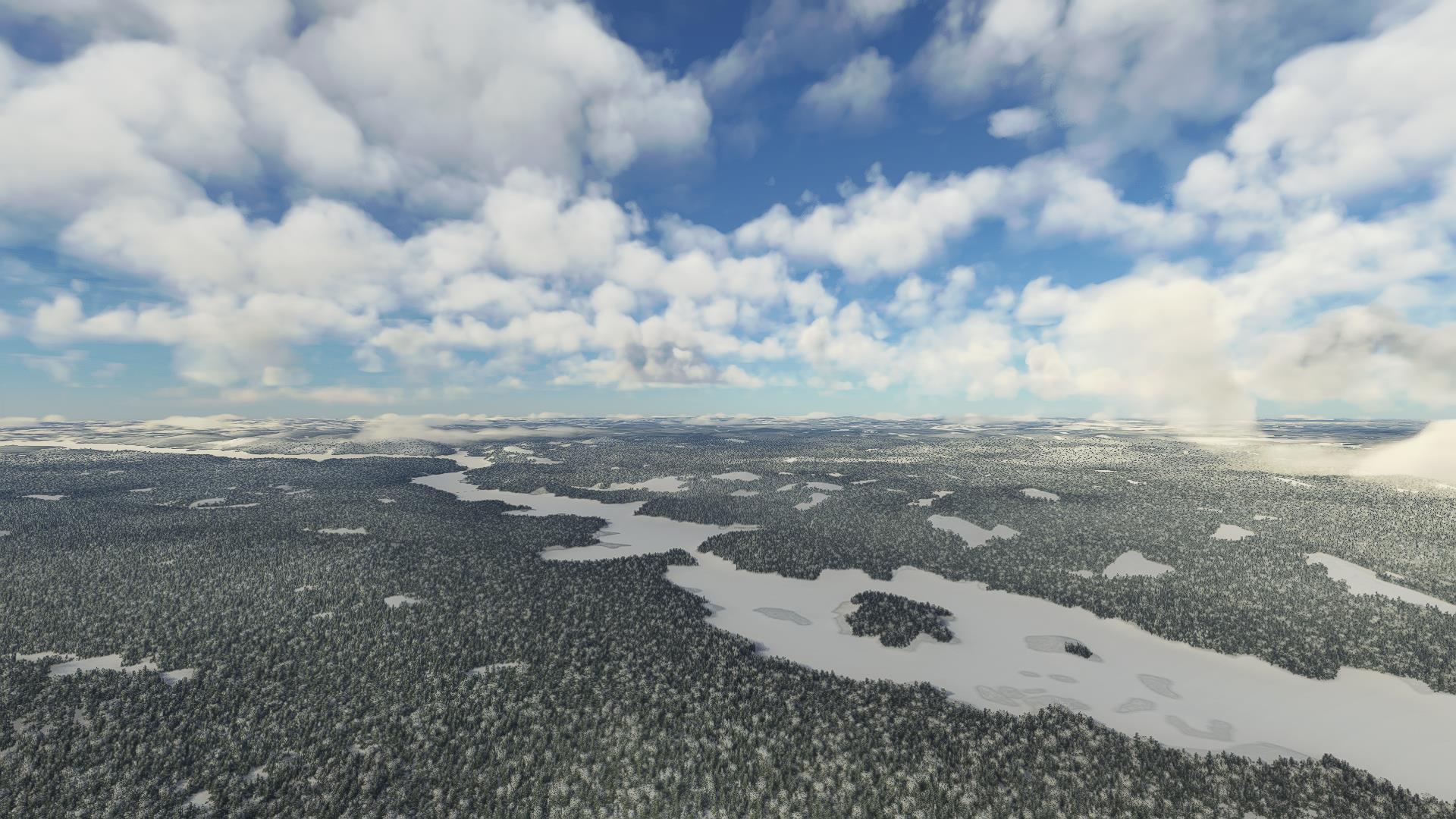

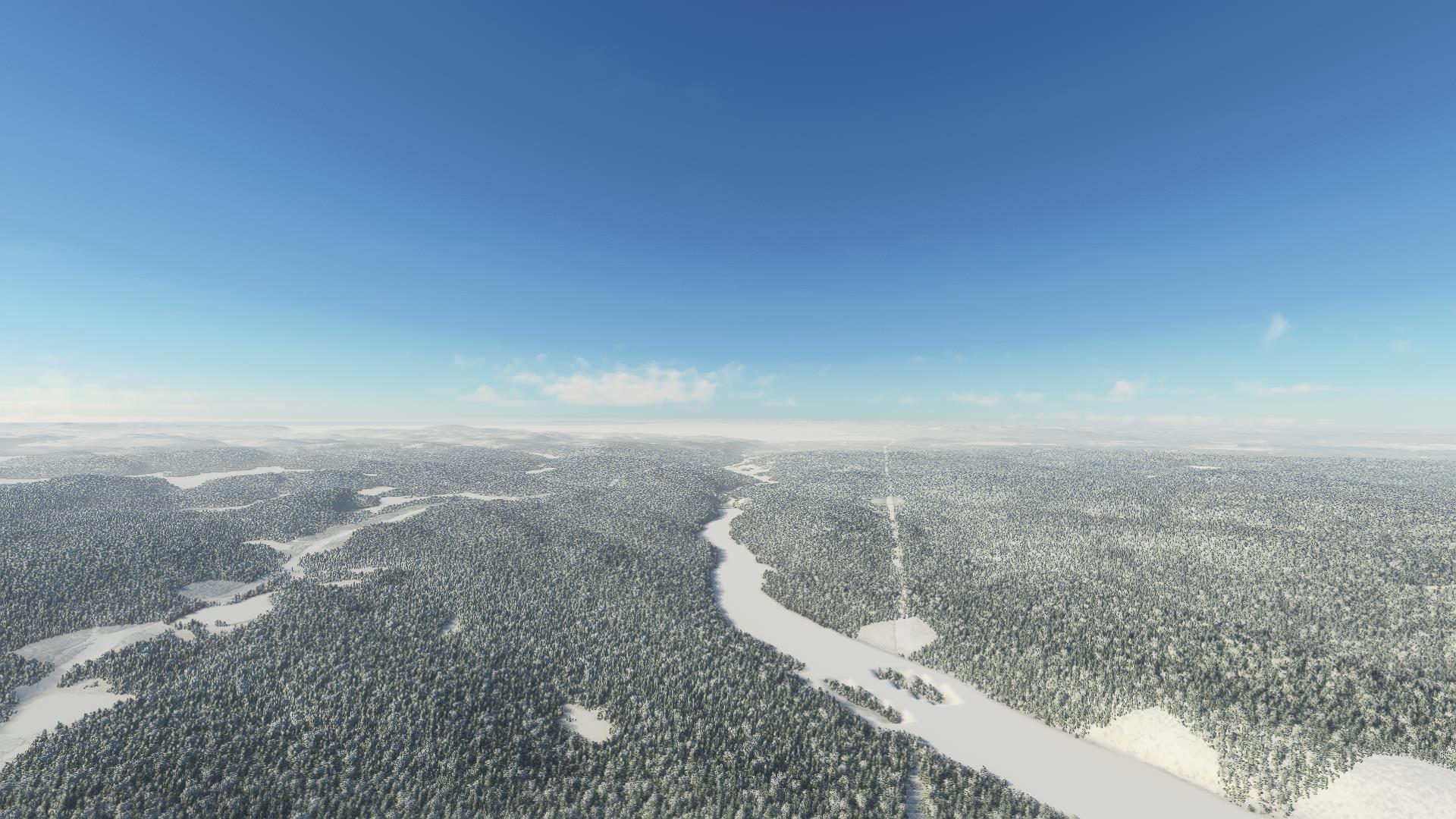

Michipicoten River. It's quite a paddle, but you can make it to James Bay this way.

Michipicoten River. It's quite a paddle, but you can make it to James Bay this way.

|

And our destination for today, Wawa.

And our destination for today, Wawa.

|

If our weather holds out, tomorrow we're off to see Nanabijou.

If our weather holds out, tomorrow we're off to see Nanabijou.

|